GLASS MODEL / PLEXIGLASS / 3D PRINTING / CLEAR RESIN

GLASS MODEL /

PLEXIGLASS /

3D PRINTING /

CLEAR RESIN

A FAMILY STORY

3rd generation of glass blowing

1952

François MULA

– Awarded as “best craftman of france” in 1952

– Founder of F. MULA Father & Sons company

2003

Daniel MULA

– Glass blower

– Founder of Glass Model Family company

2004

Vincent & Romain MULA

– Business recovery & expension of Glass Model

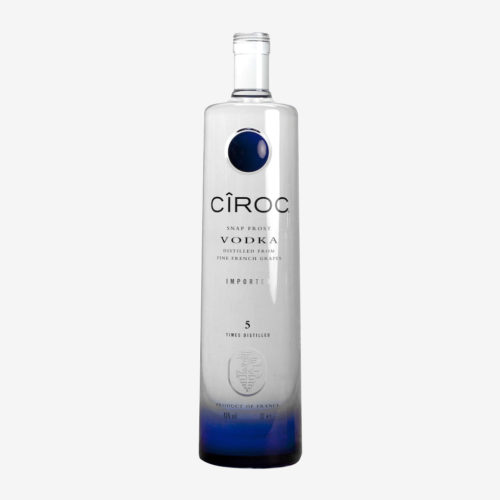

Glass Model has been specialising in the manufacture of hollow glass prototypes since 2003. We make mock up in plexiglass and 3D print since 2006 too.

As the current market leaders in prototypes for the beer, wine and spirits industry. We work with glassmakers and designers throughout the world, we know that the high quality of our pieces will meet your expectations.

The quality of our prototypes will not only enable you to persuade your clients but also to confirm a shape, a weight of glass and even the appearance of an engraving and thus avoid a glass test. Our models can enable consumer testing, tests of your bottling lines, point of sale advertising and many other time-saving applications.

Our bespoke pieces can be filled and used functionally in the same way as a container coming off a production line.

I hope that this information will make you want to know more about our business.

Please feel free to contact us.

OUR SERVICES

GLASS

A perfect way of enabling a future project to take shape.

The glass prototype can be labelled, decorated, filled with alcohol and sterilised if required.

With this mock-up, not only can the shape be checked, but consumer testing can be carriedout (the bottle can be opened and the contents consumed).

Material: Borosilicate glass 3.3

Precision: tolerance +/-0.3 mm

Weight: Mock-up standard tolerance 15% – Prototypes can be made by weight on request

Colour: Any colour, to order. Can be plated.

Finish: Any type of engraving (engraving, relief, multiple levels, coat of arms, etc.)

Bottle closing methods: Any type of screw-top, twist-off and any other closing method that isreliable and leak-proof when packaged.

High resistance to thermal shock

Requires a 3D file in . igs or . stp format

PLEXIGLASS

The best transparency and precision for prototypes that cannot be made from glass. Please note : Plexiglass® mock-ups cannot be left filled with alcohol for any length of time.

Material: Plexiglass®

Precision: tolerance +/-0.3 mm

Machining: Full or empty prototype

Colour: Any colour, to order. Can be plated.

Requires a 3D file in . igs or . stp format

3D PRINTING OPAQUE AND TRANSLUCENT

The fastest and most cost-effective way of roughing out a design. An ideal solution for fine-tuning any secondary packaging.

We can make large batches within short time frames.

Material: FDM, STEREOLITHOGRAPHY

Precision: tolerance +/-0.3 mm

Requires a 3D file in .stl format

CLEAR RESIN

Permit to make hollow prototype of any shape without partline. This technic produce high quality packaging prototypes with a beautiful transparency. The mock up can be filled with dummy liquid and decorated.

Requiring the manufacture of a silicone mould, this solution is ideal for small series.

Material: transparent resin

Accuracy: +/- 0.4 mm on diameters

+/- 1 mm on height

Requires a 3D file in . igs or . stp format

OUR CUSTOMERS

11 ZAC du mont guillerme

38780 Oytier-Saint-Oblas

FRANCE